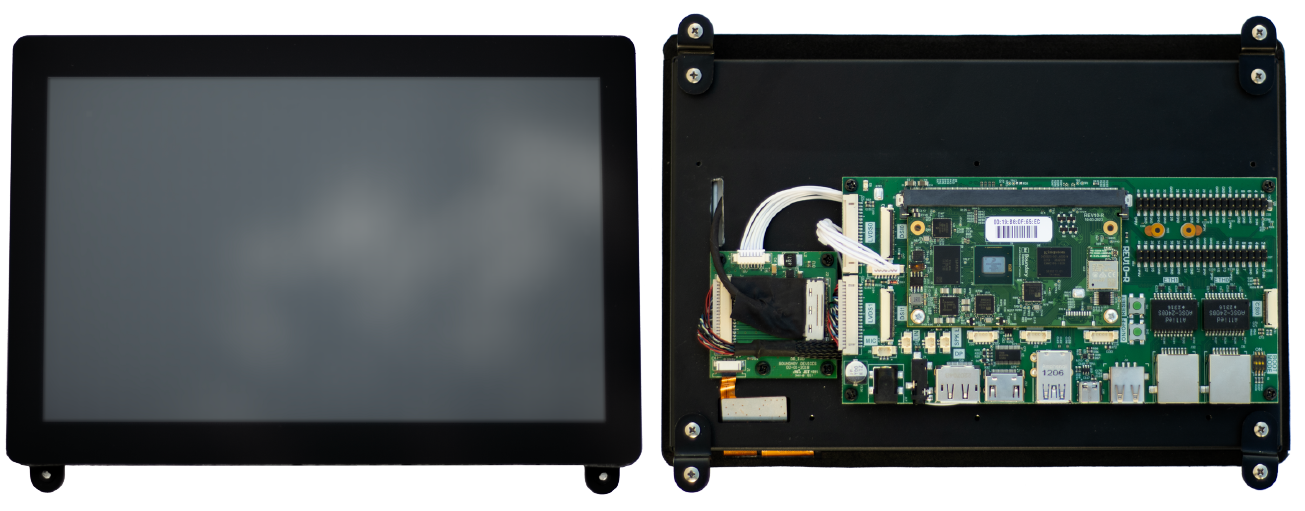

Hardware

An industrial HMI is filled with numerous components such as the display, processing units, peripherals, memory, connectivity, and more. All of these components can be tweaked and customized for its specific use case.

Display: There are two types of touch display interfaces commonly used: resistive and capacitive. Resistive displays operate by pressing two layers together, registering input. They’re durable, cost-effective, and work with any touch tool, ideal for industrial settings where gloves or wet environments are used. The second type are capacitive screens, used in smart building applications, which respond to the electrical properties of the human body, supporting multi-touch and enabling clearer images. Depending on the use case, the need for multi-touch functionality or a robust display can be selected.

Processor: The graphical interface of the industrial HMI is important, but just as critical are the capabilities of the HMI’s responsiveness: how effectively it can manage data and execute the software depends on the underlying processor. There are a range of processors from Intel Atom, Qualcomm Snapdragon and ARM processors that support powerful computing capabilities and rich graphical interfaces in this class of devices. However, ARM processors are often preferred for their energy efficiency, cost-effectiveness, and longer lifecycle, especially in applications where power consumption and space are critical. ARM’s architecture also allows for greater flexibility in customizing the processor for specific tasks, such as signal processing, managing user inputs, interfacing with sensors, and implementing security protocols to safeguard data.

Working with an embedded systems supplier such as ourselves, who have expertise in system-on-modules (SOMs) and single board computers (SBCs), brings distinct advantages. Rapid customization, flexibility, easy maintenance, and future-proof compatibility are a few of the reasons that choosing a single, full-solution HMI supplier can help bring your HMI design quickly to market. Ezurio’s partnership with leading semiconductor manufacturers gives us access to a wide range of processors from the versatile NXP i.MX 6, 8, and 9 families to MediaTek’s powerful Genio family. This expertise and these partnerships allow Ezurio to be one of the only suppliers in the marketplace to provide a full industrial HMI solution with customizable embedded hardware. It enables us to create the perfect HMI solution to fit your requirements.

Connectivity: Connectivity in HMIs is vital for effective communication and control in industrial systems, enabling real-time data exchange and remote monitoring. Both wired and wireless connections are used to increase operational efficiency. Wired connectivity (via Ethernet, RS485, CAN RS232, and USB) provides robust and reliable communication, allowing fast data transfers crucial for complex operations and quick response times. For example, using Ethernet to link to an HMI with a Programmable Logic Controller (PLC) allows operators to instantly monitor and adjust production lines, ensuring timely responses to any issues that arise.

Alternatively, wireless connectivity in HMIs offers additional advantages of flexibility and mobility, crucial for industrial and commercial environments where changes occur rapidly. Ezurio leverages our decades of experience in wireless technology to maximize the benefits for industrial HMIs using our latest Wi-Fi 6 and Bluetooth 5 wireless modules. With Wi-Fi 6, features like OFDMA and MU-MIMO ensure reliable, high-speed communication over wide areas, making it ideal for tasks that require quick data transmission across large facilities. Similarly, Bluetooth 5, with its enhanced range and speed, is perfect for precise, energy-efficient local tasks such as equipment diagnostics or updates. This combination ensures industrial HMIs can operate more efficiently and responsively in dynamic environments.

Services

Along with the hardware mentioned above, services are a huge component of an industrial HMI solution. Ezurio leads our competitors in providing extensive options to reduce your design risk and bring your HMI interface to market faster. With a US-assembled HMI solution, our engineering, assembly, and support teams are all under one roof, streamlining the development process. For instance, our partnership offers both standard and customizable HMI solutions that are fully pre-certified, and they’re ready for integration with our software application.

Purchasing an HMI solution usually brings in multiple component suppliers. The display, embedded system, wireless connectivity, and peripherals are supplied by various vendors which often leads to headaches if component discontinuation or allocation comes to play. Ezurio, a single full HMI solution provider, manages all of the components, mitigating BOM and supply challenges. Let our experts cover all the details – we help you focus on developing the HMI solution that perfectly suits your unique needs.

Software

Ezurio provides the foundational operating system for industrial HMI applications, available in Yocto Linux, Buildroot Linux, Unbuntu, android, and RTOS, among others. This approach allows engineers design choice in developing and loading their custom applications onto HMIs, offering flexibility to tailor the system to specific use case needs. This base operating system allows developers to have flexibility from their HMIs, being able to optimize for efficiency, responsiveness, or user experience while delivering on critical performance and functionality.

For software integration, Ezurio and its SaaS partners assist the transition of your HMI application from local devices to web-based control, improving HMIs with capabilities for advanced cloud-based functionalities, such as data analysis, real-time monitoring, automation triggers, and device management.

Emerging Trends

Looking towards the future of HMI, emerging trends like augmented reality (AR) interfaces, voice controls, and advanced gesture recognition are set to redefine user-machine interactions, making interfaces more intuitive and user-friendly. To keep up with the changing technological landscape, companies must be sure that they are considering future-proofing options to minimize downtime and costs for improving their future HMI displays.

Ezurio’s engineering team can work with you to not only future-proof your design, but also recommend the best course of action to upgrade when the time comes with our latest modules and embedded systems.

Learn more at https://www.ezurio.com/product/industrial-hmi

Laird Connectivity is now Ezurio

Laird Connectivity is now Ezurio