Protecting the Cold Chain with IoT Sensors

Published on March 16, 2020

The Problem: Critical Needs and Imperfect Solutions

From frozen french fries to life-saving medications, many products must be carefully monitored from manufacture through to the point of sale to be sure they’ve been kept at safe temperatures. At every step of the journey, from harvest, processing, distribution, and the retail level, maintaining safe temperatures for those products can be the only thing protecting consumers from food-borne illness, spoiled biologic pharmaceuticals, and other serious problems.

The means that have been used historically to keep up with the cold chain have been the same: refrigeration systems fitted with temperature gauges, which are regularly monitored and logged by staff to ensure compliance. But with the availability of low-cost, low-power IoT sensors, these old systems are increasingly viewed as too much work, and out of date. Worse, there are lots of failure points where simple human error can lead to noncompliance, spoilage, and illness.

In this blog post, we’ll look at the ways sensors can replace tedious and erroneous human involvement in the measuring and logging processes of the cold chain. We’ll also look at the ways in which a network of sensors provide the dual benefit of increasing accuracy and decreasing costs for manufacturers, shippers, and retailers.

Real Accountability – The True Advantage of IoT Sensors for Cold Chain

As previously mentioned, the procedures that historically have defined cold chain measuring and compliance are decidedly low-tech: Human monitoring, logging, and paperwork. Staff are tasked with taking notes at various time intervals to read a thermometer and sign off on the reading with their initials. In principle, this has served the need fairly well overall. But it’s an imperfect system that is vulnerable to human error, which manifests itself in lots of ways.

The reality on the ground in most places is also the same. Workers have more responsibilities and less time as most businesses strive to be more efficient and more productive. And with that increased pressure comes an increased likelihood for mistakes. Employees can sometimes misread a measurement in haste, or in worst case scenarios simply fill out the expected measurement and move on. Accuracy suffers, and there’s no way retrospectively to prove out the recorded data.

This is a liability for every single piece of the cold chain. When you consider how many people, refrigeration units, and locations are involved in this process, you can begin to appreciate exactly how many opportunities this system has for failure. Everyone involved must diligently perform these tasks with complete accuracy every time in order for goods to be protected. It only takes one failure to put that product at risk.

This is where the real opportunity exists with wireless IoT sensors – generating true accountability in the system. Wireless sensors, which report their own temperature data back to a cloud-based monitoring system, provide a new degree of certainty. A wireless sensor reading is physical evidence of the conditions inside a refrigeration unit, and not simply a human attestation of those conditions. They can take readings much, much more often than a human can be expected to log them. And in the event of a failure or an out-of-bounds reading, they can alert maintenance staff to a problem in a much faster response window than is possible with human monitoring.

Return on Investment – How IoT Sensors Provide Exceptional Value

Wireless IoT sensors can provide more readings in more places than is possible to achieve with human reading and logging. Those readings can be regarded with a higher degree of trust. And importantly, this can be done in a highly cost-effective manner.

Wireless IoT sensors enable personnel to focus on more important tasks, rather than the tedium of logging temperatures across a facility. That enables them to be more efficient, only being dispatched to a refrigeration system when it fails. A cloud application can log temperatures and flag fail conditions, freeing up employees to spend more time in places where a human is more needed.

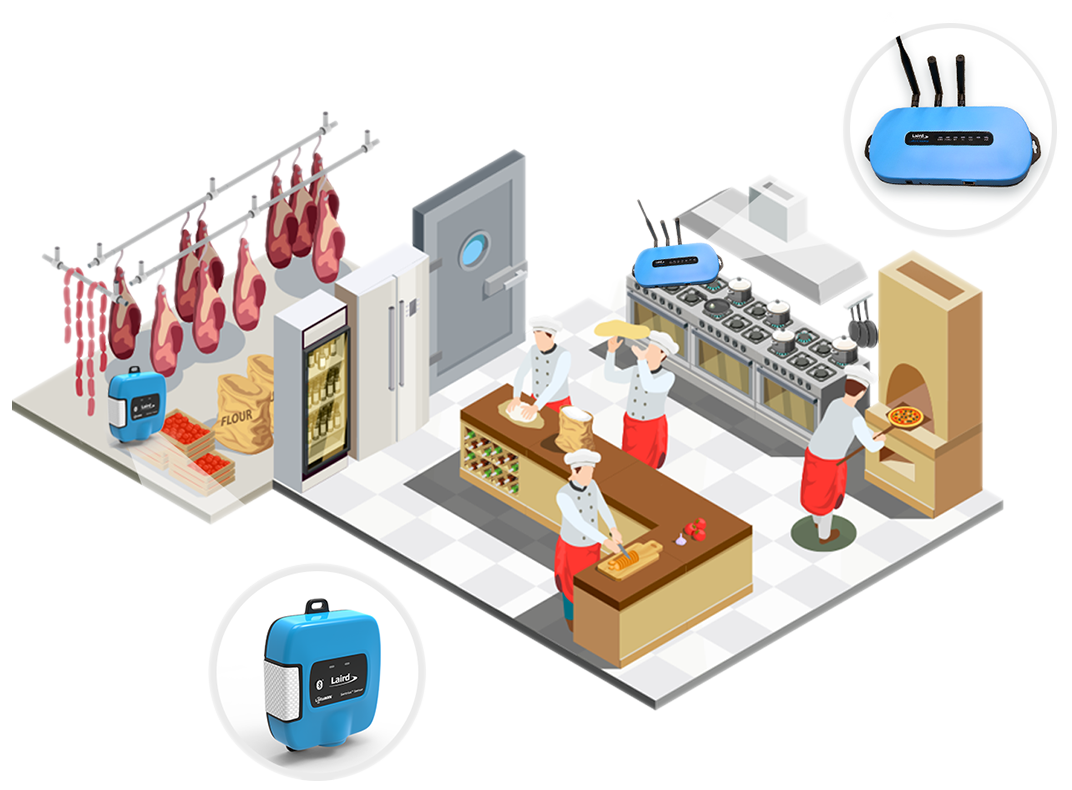

IoT sensors are easy to install, and once installed require very little maintenance. Low-power features on IoT sensors, such as our Sentrius™ RS1xx Temperature and Humidity sensor, allow you to deploy a device for years with little maintenance, all powered by a simple coin cell battery. They can be mounted to a wall, placed within range of a gateway product like our Sentrius RG1xx gateways, and begin gathering highly reliable, up-to-the-minute data with no further involvement for years.

All of this is a tremendous value by comparison to the cost of failure. A spoilage or recall event is a serious threat in terms of recall costs, illness, and ultimately lack of trust. The examples are numerous, and the damage to a brand can be very hard to overcome once a contamination event occurs. Many brands have suffered lack of public trust for years after experiencing a recall, something which can often be prevented with the granular level of detail inherent in wireless IoT sensors.

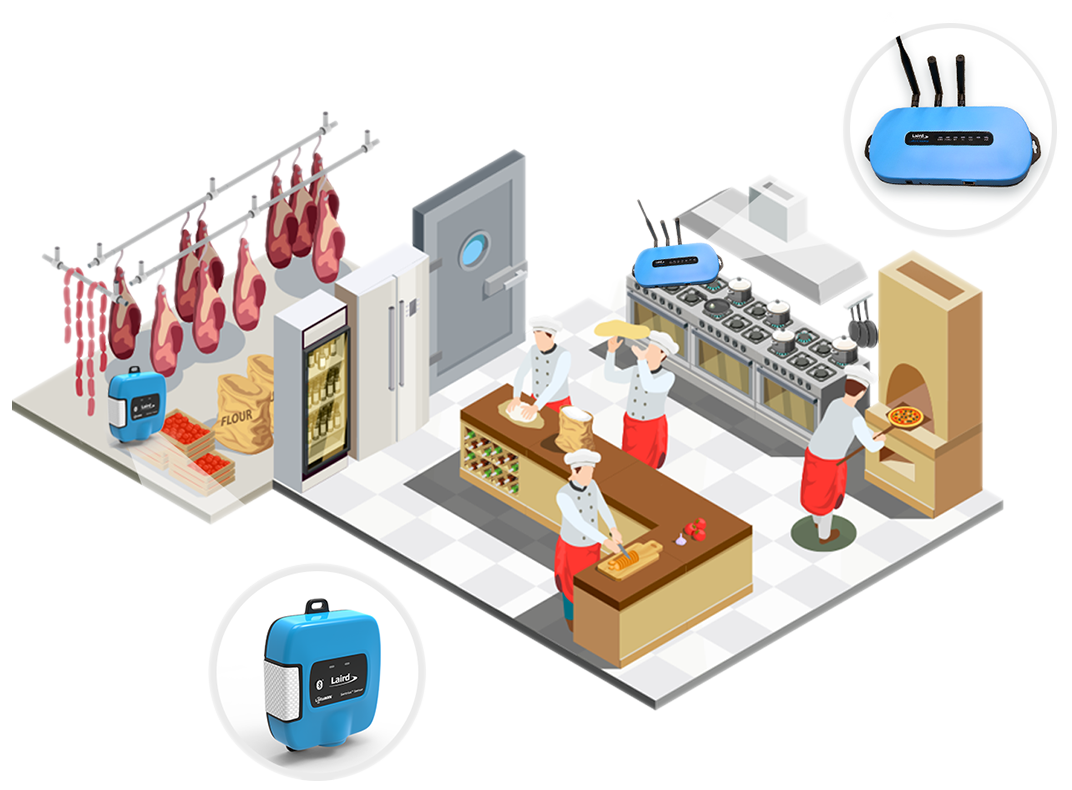

The Ezurio (formerly Laird Connectivity) Solution – Wireless IoT Sensors and Gateways

Ezurio provides multiple wireless sensors and gateways that are custom-tailored to many common cold-chain use cases. Our Sentrius RS1xx sensors are available with internal temperature and humidity sensors, with an external probe for measuring interiors, and even with open/close sensors you can use to ensure doors are shut and temperatures are stabilized. They are easily configured for operation with our RG1xx Gateways, which can connect with multiple sensors and send that data up to the cloud over Wi-Fi or Ethernet for further processing.

Importantly, we also provide starter kits to demonstrate how you can quickly and easily set up gateways and sensors with Amazon Web Services right out of the box and almost immediately begin polling sensors for realtime updates. Our IoT Starter Kits features the IG60-BL654 + BT510 Starter Kit, with more kits on the way.

Learn more at our IoT Devices page.

Laird Connectivity is now Ezurio

Laird Connectivity is now Ezurio